Where the oilfield works.

Wellsite™ gives you a real-time view of wells, crews, and activity across the oilfield.

Free to start. No credit card required.

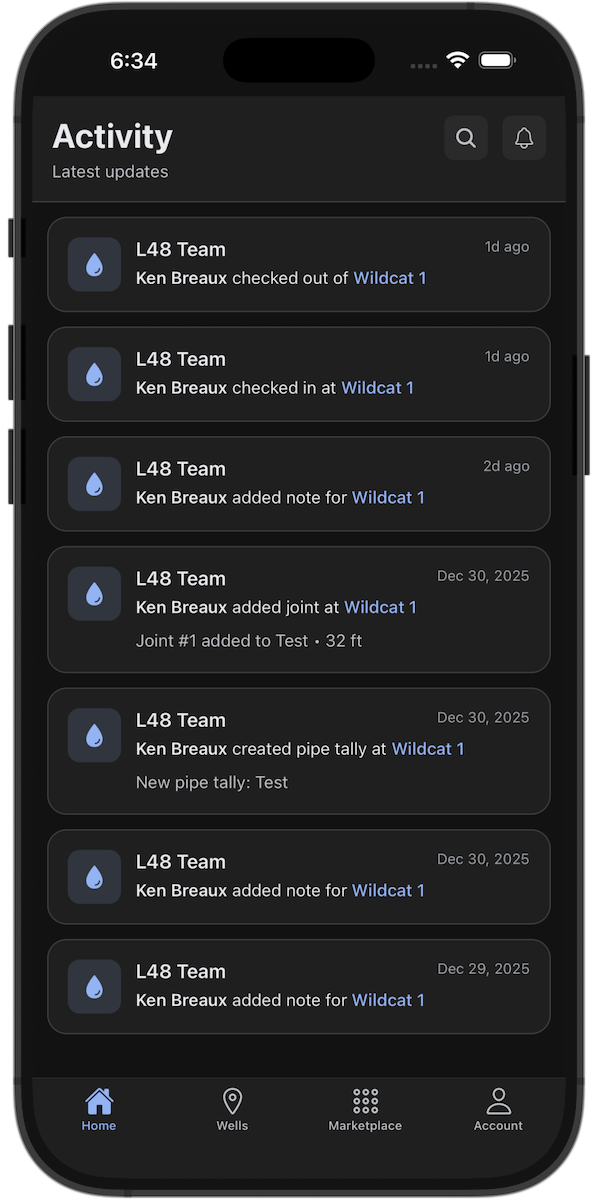

Stay connected to the field

Wellsite™ keeps you connected to what's actually happening in the field — so work isn't scattered across texts, calls, and spreadsheets.

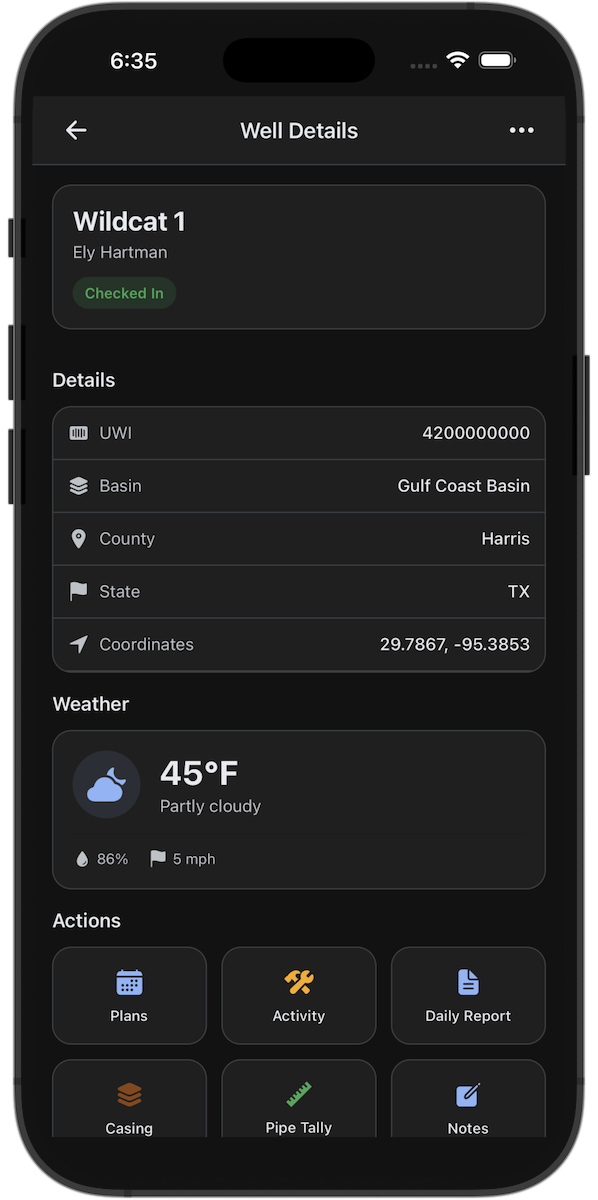

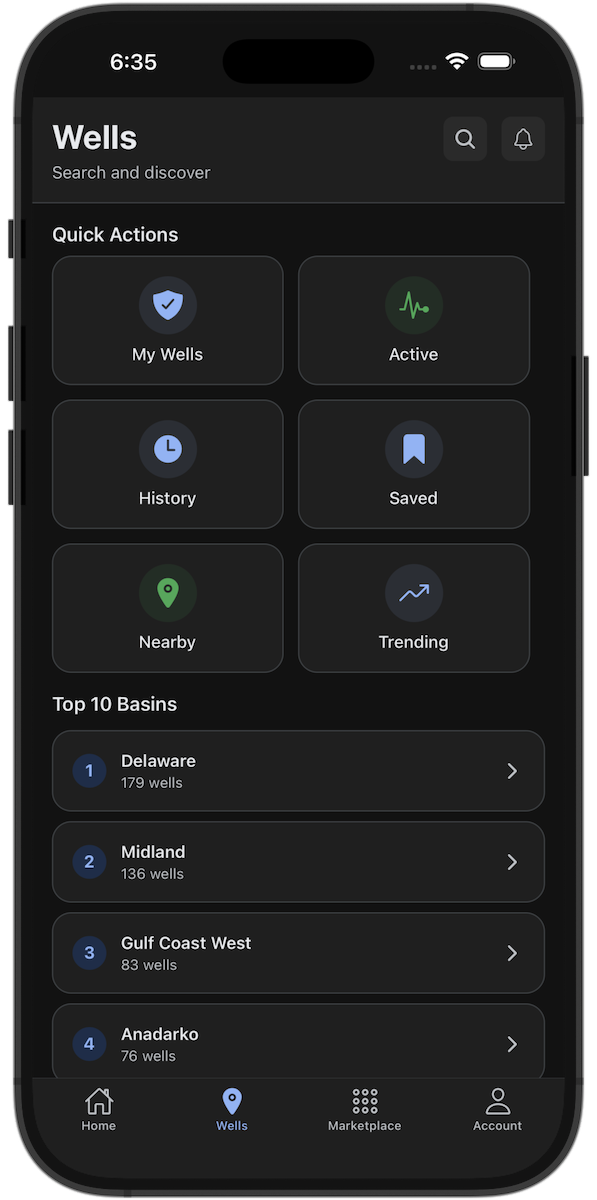

From permit to production

Track rigs, frac spreads, permits, and production across every basin.

Drilling

Track pad construction, rig movement, and spud timing. Know when operators are mobilizing before permits hit public record.

Completions

Follow frac crew movement and stage progress. See when wells enter flowback and prepare for what's next.

Production

Monitor first oil, DUC drawdowns, and ramp-ups. See which wells are coming online and where.

Choose your experience

What our customers say

“Wellsite puts my team where the work is happening—not where it happened last month”

Bailey Midkiff

- VP of Sales