Digital transformation has become a disruptive force in the oil and gas (O&G) industry. It is no longer viable for upstream oil and gas operations to remain competitive while relying on outdated technology. O&G companies that face competitive pressures use production optimization, workforce streamlining, and contract renegotiation to improve their bottom lines. But innovative oil and gas executives realize that digital platforms can provide a more robust solution for cost optimization. Digital transformation can save the upstream oil and gas industry $100 billion to $1 trillion by 2025 in capital expenditures and operating costs. So, the O&G companies have a vested interest in paying attention to the latest innovations in digital technology.

For upstream operations, digital applications can create unprecedented synergy between drilling rigs, production sites, and back offices. The use of technologies like cloud computing, real-time analytics, the Internet of Things (IoT), smart drones, machine learning, and manufacturing execution systems (MES) can help with digital transformation. But data is at the center of all of these tools and applications. Upstream O&G operators need reliable data acquisition and transfer to use digital tools to make better decisions and improve operations. WITSML is an industry-standard playing an essential part in the digitization of drilling data. The recent version 2.1 of WITSML with the ETP 1.2 transfer standard has opened up new possibilities for the fast transfer of trustworthy drilling data.

WITSML 2.1 and ETP 1.2 Standard: An Overview

Data flows and transfers require standards. Without proper standardization, data management can become chaotic. WITSML is an oil and gas industry standard developed by Energistics to transmit data from rig-site to various stakeholders like operators, integrators, and service companies. WITSML helps the industry maintain data structure and design compatibility across multiple domains of oil and gas exploration and production (E&P).

Energistics: The Organization Behind WITSML

Energistics is a global non-profit organization with an open consortium to define, develop and maintain data standards for the upstream O&G industry. It has been around for more than 25 years.

Energistics membership consists of leading E&P companies, regulatory agencies, software vendors, and system integrators. Members play leadership roles in defining the open data exchange standards. The Special Interest Groups (SIGs) bring domain specialists together to define specifications for particular domains. The “Drilling, Completions and Interventions SIG” handles WITSML. Energistics also has SIGs for production data (PRODML), reservoir model and interpretation data (RESQML), and common standards.

The organization performs the technical implementation, testing, and maintenance of the standards developed by the SIGs. The common technical architecture for drilling, production, and reservoir helps with universal data interoperability. It provides the vendor-neutral infrastructure for experts in which oil and gas industry domain specialists can collaborate to develop and promote the standards. The Energistics specifications are freely available. No membership is required to access the specifications, documentation, and examples.

WITSML: A Standard for Wellbore and Drilling

WITSML stands for Wellsite Information Transfer Standard Markup Language. The standard has been around for 15 years. It shouldn’t be confused with Wellsite Information Transfer Specification (WITS).

Even though both WITS and WITSML share the same goal of transferring data efficiently, the two standards defer in methodology. The oil and gas industry developed WITS in the 1980s. The WITS standard uses a binary file format to share drilling information. In contrast, WITSML is a web-based technology that uses XML to transfer data without depending on a particular platform or language.

The primary goal of WITSML is to reliably transfer wellbore and drilling-related real-time data to various operation centers. However, the standard also makes it easy to move well-related data between multiple applications and helps operators monitor the real-time availability of drilling operations.

WITSML deals with various categories of data. The reference objects transfer static data about things that rarely change, like well or wellbore. The growing objects deal with data that change over time, like logs, trajectory, or mudlog. Also, the standard has provisions for moving snapshot information to create reports. WITSML has two essential components - a set of XML schemas and an Application Programming Interface (API). The XML schemas define the various objects that are pertinent to drilling. For example, a well would be one of the objects. The number of objects differs between various versions of WITSML. WITSML 1.4.1 has 27 primary objects, while WITSML 2.1 has 29 primary objects. The API defines how to interact with the objects. A developer can use the API to add an object to a store or get an object from a store. The simple API methods allow straightforward and effortless data management.

The New Challenges for WITSML

Over the years, WITSML has become the de-facto standard for the drilling industry. However, the requirements for WITSML have evolved. The industry has new challenges that WITSML needs to address.

- Big Data and Analytics: Drilling rigs produce more data, and operators have to process the data. Service companies have to deal with millions of WITSML requests.

- High-frequency, Low-latency Data: Companies want to transfer more data at lower latency to make real-time decisions from offshore offices.

- Workflow Flexibility: Businesses no longer are satisfied with data flowing from wellsite to office. They want options to transfer data between applications. They also want ways to archive data for regulatory compliance and expand metadata to track the quality of the data.

WITSML 2.1: A Solution for the New Drilling Frontiers

WITSML 2.1 addresses the new requirements of the oil and gas drilling industry. WITSML SIG has redesigned some data objects and removed unused data objects to improve the standard.

Here are some ways WITSML 2.1 provides more value for the oil and gas industry:

- Integrated: The initial versions of WITSML, PRODML, and RESQML were developed by various companies in silos. So, the standards were not compatible with each other. However, WITSML 2.1 is designed to have a common technical architecture with PRODML 2.2 and RESQML 2.2. With the common architecture v2.3, data sharing between standards is more accessible.

- Programmer Oriented: The new WITSML 2.1 is more programmer-friendly. Energistics has simplified the XML schema structure and improved the documentation. It is also providing open-source code and devkits to help developers. Easier development options should lead to more adoption.

- New Workflow Support: WITSML 2.1 supports server and serverless data transfer. In the previous versions of WITSML, operators needed to use servers to process data. In the new version, the serverless data transfer capability enables trustworthy, secure, low-latency data streaming. Also, the 2.1 standard supports archival workflows and expanded metadata for data quality assessment and assurance.

- Major Transfer Protocol Change: WITSML 2.x has deprecated legacy SOAP API that was used in the WITSML 1.x versions and replaced it with ETP. ETP allows real-time data transfer.

ETP 1.2: Opens New Ways for Real-time Drilling Communication

Energistics Transfer Protocol (ETP) plays a vital role in the new WITSML 2.1 standard. In previous 1.x versions of WITSML, Simple Object Access Protocol (SOAP) was used for data exchange. But the new ETP 1.2 data exchange specification enables efficient data exchange for WITSML 2.1. The main benefit of using ETP is real-time data transfer. No server is necessary with the new data transfer protocol. It allows direct communication between data producers and data consumers.

ETP sends and receives predefined messages. In an actual world situation, an application can use the protocol to open a communication channel with a sensor on the drilling rig and ask the sensor to stream real-time data. The communication does not require intermediary servers. ETP is also part of PRODML and RESQML. The transfer protocol uses WebSockets. The main use cases for ETP real-time data transfers are:

- Server Transfer: Move data from a wellsite provider to a WITSML store.

- Replication Transfer: Transfer data between WITSML stores.

- Application Transfer: Transfer information from the WITSML store to client applications.

Before ETP, when an operator queried data, the information had to be collected through a chain of stores. The first server would query the second server; the second server would query the third server; and so on until the system found the relevant information. The process introduced significant delays and limited the possibility for real-time instantaneous data transfers. So, ETP direct channels cut down latency to enable real-time communication.

WITSML 2.1 and ETP 1.2: Drilling Digital Transformation

The upstream oil and gas industry already understands the value of digital technologies. Implementing digital technologies is part of the core strategy for many companies who want to build efficient, profitable, and sustainable businesses. Organizations are looking into systems and digital platforms that take advantage of the cloud, big data, machine learning, predictive analytics, IoT, cognitive systems, and more. But businesses cannot trust the systems without reliable data. WITSML 2.1 provides the essential foundation for reliable data acquisition and transfer. Moreover, the drilling industry needs fast, real-time data transfer to take advantage of the systems they are putting in place. ETP provides real-time data transfer to help companies decentralize their decision-making processes.

Here are a few drilling use cases that WITSML 2.1 and ETP 1.2 are helping with:

Identifying and Reducing Non-Productive Time

Rig-related non-productive time (NPT) is a massive headache for drilling contractors and operators. To reduce NPT, drilling service providers need efficient ways to identify problems. NPT can be caused by unpredictable weather or technical issues. Even though it is impossible to counteract all NPT factors, operators can decrease the probability of downtime if reliable data is delivered promptly.

As modern onshore and offshore rig equipment has become software dependent, the application-generated data points are a valuable source of information. Operators can monitor data points remotely to identify power generation systems and fluid equipment problems. It means real-time data transfers can help oil and gas rigs identify issues faster. Drilling service consultants can use predictive analysis to take problematic systems offline and use backup systems to reduce non-productive time. NPT analysis can be coupled with risk management to increase overall drilling performance. WITSML 2.1 and ETP 1.2 provide the real-time data transfer backbone for control systems to recognize NPT-related issues.

Better Collaboration on Remote Drilling Projects

ETP-based real-time data transfer is a game-changer for drilling companies that deal with remote sites. Without real-time data access, drilling service companies have to fly service personnel regularly to the rig sites. Physical transport is expensive, time-consuming, and inefficient. ETP allows rig sites to deliver high frequency, low latency data streaming to real-time operating centers(RTOCs). Engineers can monitor the health of the equipment and systems without taking field trips. The reduction of on-site personnel leads to cost savings.

Real-time operating centers are a paradigm shift for the industry. But the upstream oil and gas companies need to develop or acquire digital platforms to gather relevant data. They need software and applications that can control the equipment remotely. Organizations also have to train their employees to use remote guidance systems for rig equipment. However, the investment in software and training will save time and money and lead to more collaborative remote site management.

Save Millions in Drilling Operations

The uncertainty of oil and gas prices has created pressures for the industry to find innovative ways to save money. Implementing WITSML 2.1 and ETP 1.2 for drilling operations is a pathway to a better future. The real-time data can help rig crews monitor drilling equipment setup and improve maintenance tasks. Predictive analysis can help engineers better understand systems and prevent disasters. Oil and gas rigs can be run with a centralized pool of specialists, thus reducing operational costs. So, upstream oil and gas companies can save millions through the use of WITSML 2.1 and ETP 1.2.

In Conclusion

Digital disruption is not comfortable for the upstream oil and gas industry. The O&G industry has been around for a long time, and it has developed specific ways of getting the job done. However, traditional methods of running drilling rigs might not help companies stay competitive in the twenty-first century. WITSML 2.1 and ETP 1.2 provide an opportunity for upstream operators to modernize their oil and gas rigs. They can improve the underlying systems while taking advantage of new technologies. The new standards can help companies reduce the time and resources needed for data validation and verification, make more informed decisions, and respond faster to operation disruptions. WITSML 2.1 and ETP 1.2 standards are paving the way to make drilling more efficient and cost-effective.

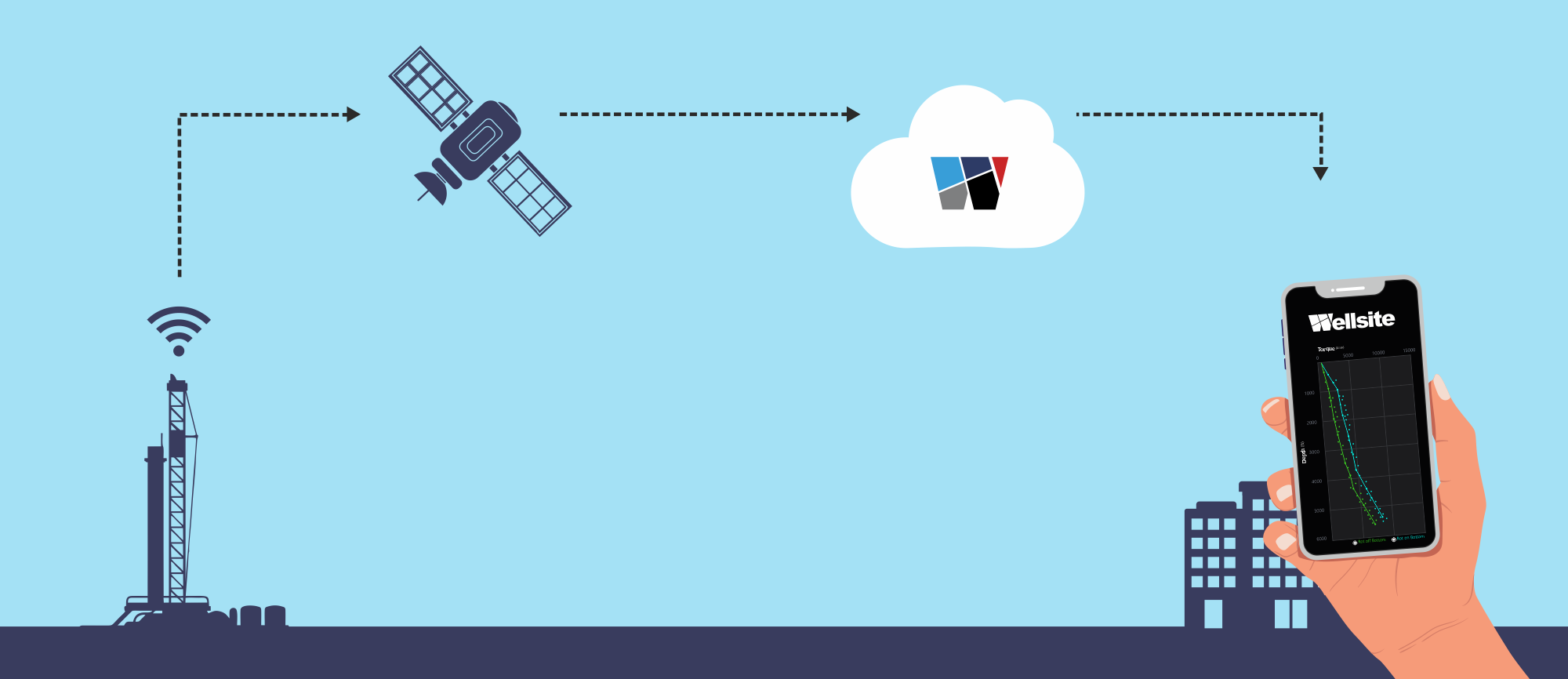

Wellsite™ connects remote drilling and completion operations and provides real-time data, analytics, and tools to help you make better decisions faster. Contact us today to learn more.

Research:

https://www.pwc.com/us/en/industries/energy/digital-in-energy.html

https://www.strategyand.pwc.com/gx/en/insights/2020/digital-operations-oil-and-gas.html

https://www.strategyand.pwc.com/gx/en/insights/2019/the-race-to-digitise.html

https://www.strategyand.pwc.com/gx/en/insights/2018/drilling-for-data.html

http://www.iadc.org/wp-content/uploads/2019/05/GET-Up-To-Speed-on-new-capabilities-in.pdf

https://www.energistics.org/wp-content/uploads/2017/10/aug-17-perth-ppdm-witsml-ndpresented.pdf

https://www.energistics.org/membership/

https://www.wellsite.com/use-cases

https://www.energistics.org/witsml-developers-users/

https://www.energistics.org/frequently-asked-questions/

http://docs.energistics.org/CTA/CTA_TOPICS/CTA-000-021-0-C-sv2100.html

WITSML v2 0 Release Candidate Overview Webinar [https://www.youtube.com/watch?v=ptb50l-KoUg]

Energistics Webinar Digital Transformation 02 27 2019 [https://www.youtube.com/watch?v=Q1BV5pQ_OW8]

http://docs.energistics.org/#WITSML/WITSML_TOPICS/WITSML-000-000-titlepage.html

http://docs.energistics.org/#ETP/ETP_TOPICS/ETP-000-000-titlepage.html

https://uogc.com/what-is-witsml/

https://www.vysusgroup.com/articles/seven-ways-to-reduce-non-productive-time-of-your-land-rig

https://link.springer.com/content/pdf/10.1007/s13202-020-01059-0.pdf

https://www.drillingcontractor.org/rig-npt-the-ugly-truth-6795

https://onepetro.org/SPEATCE/proceedings-abstract/20ATCE/3-20ATCE/D031S022R004/449824

https://www.drillingpoint.com/p3079/driving-cost-reductions-in-drilling-operations/

https://www.energistics.org/consolidated-release-candidate-now-available/